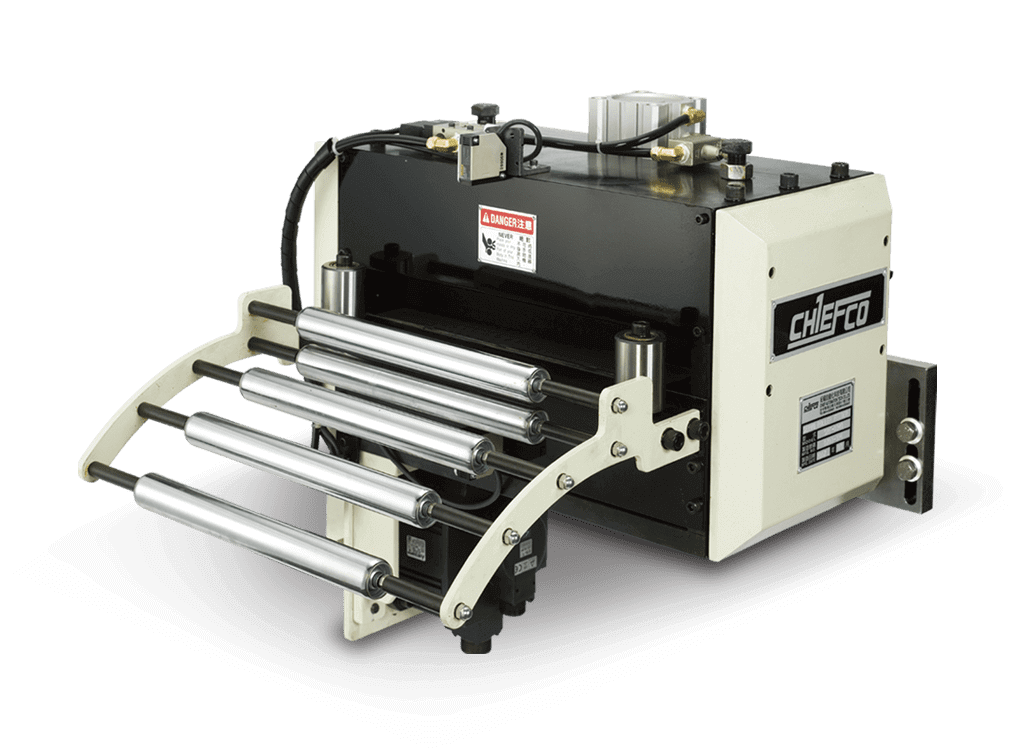

Roller Feeder Machine

- The high-rigidity side wall structure never deforms, allowing the automatic feed roller to maintain high feed accuracy.

- A special controller for the automatic roller feeder is used.

- Space saving, excellent vibration resistance and anti-interference, and ultra-fast response speed.

- The machine is easy to set up, easy to operate. Novices can get started quickly.

- The maintenance-free design has self-lubricating bearings in all the swivel parts, eliminating the need to stop the damage caused by forgetting the oil supply.

- Special design orders accepted.

SRF Series

DETAILS

| Model | 0320 | 0330 | 0340 | 0350 |

|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 500 |

| Stock Thickness(mm) | 0.3~3.2 | |||

DETAILS

| Model | 0620 | 0630 | 0640 | 0650 |

|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 500 |

| Stock Thickness(mm) | 0.8~6.0 | |||

DETAILS

| Model | 0360 | 0380 | 13100 | 03120 |

|---|---|---|---|---|

| Max. Stock Width(mm) | 600 | 800 | 1000 | 1220 |

| Stock Thickness(mm) | 0.3~3.2 | |||

| Model | 0660 | 02680 | 06100 | 06120 |

|---|---|---|---|---|

| Max. Stock Width(mm) | 600 | 800 | 1000 | 1220 |

| Stock Thickness(mm) | 0.8~6.0 | |||

DETAILS

| Model | 0320 | 0330 | 0340 | 0350 | 0360 | 0380 | 03100 | 03120 |

|---|---|---|---|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1220 |

| Stock Thickness(mm) | 0.3~3.0 | |||||||

- Can freely edit many material feed length settings, adds flexibility to any press.

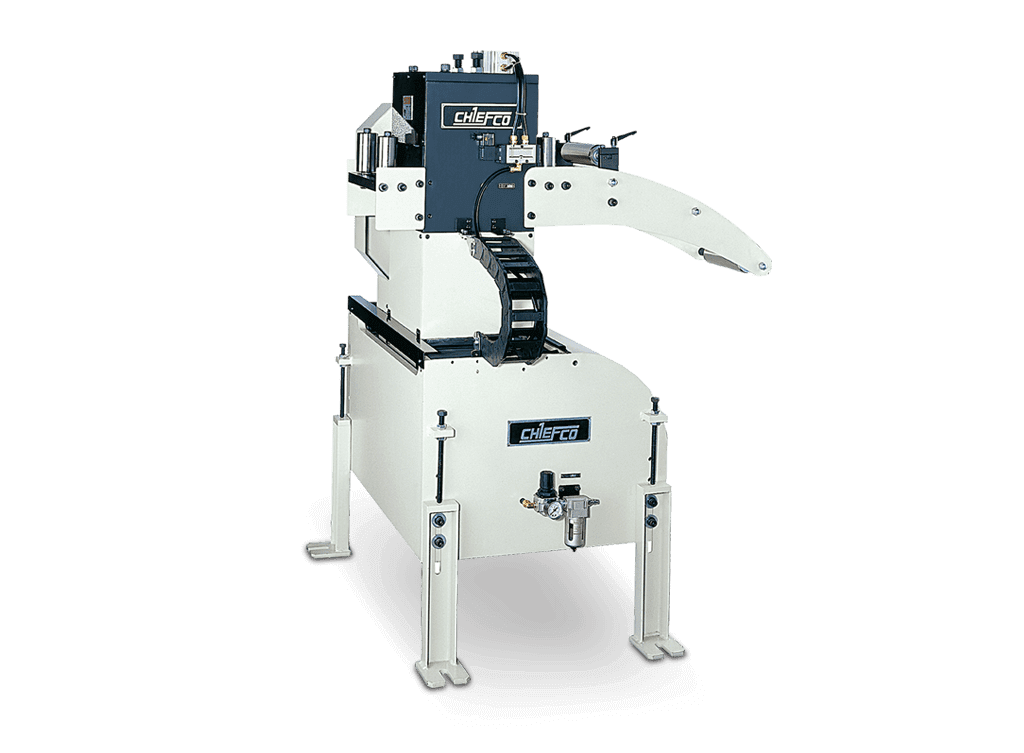

ZRF Series

DETAILS

| Model | 0320 | 0330 | 0340 | 0620 | 0630 | 0640 |

|---|---|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 200 | 300 | 400 |

| Stock Thickness(mm) | 0.3~3.2 | 0.8~6.0 | ||||

- Can freely edit many skewed movements to improce material usage and save material costs.

LRF Series

DETAILS

| Model | 0320 | 0330 | 0340 | 0350 |

|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 500 |

| Stock Thickness(mm) | 0.3~3.2 | |||

- Make the most of available floor space.

As the client's prosperity is top priority for CHIEF AUTOMATIC TECH, we adhere to the ideals of "High Quality & Excellent Service", and guarantee these as we innovate new products with attached value and high profitability.

PRODUCT INQUIRY