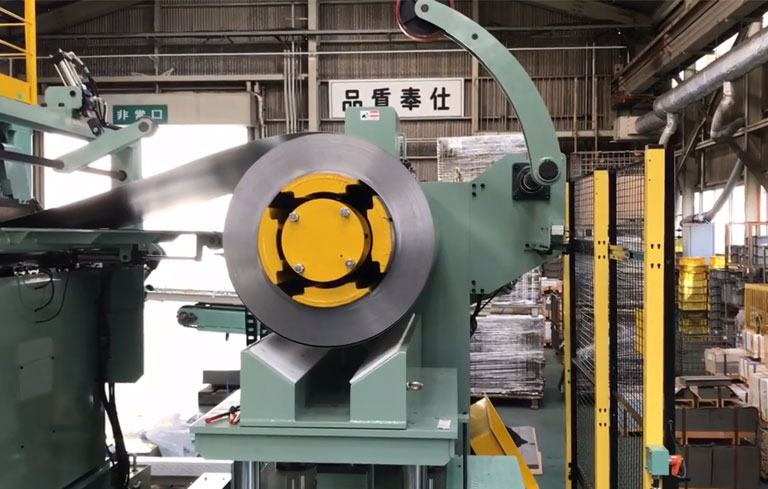

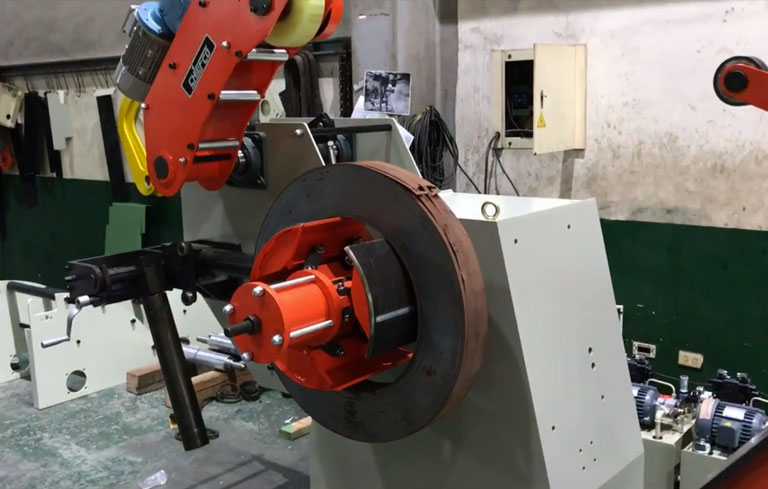

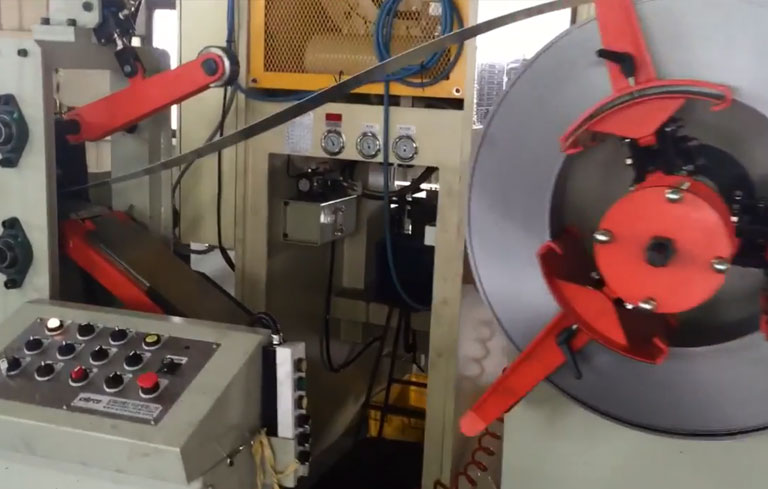

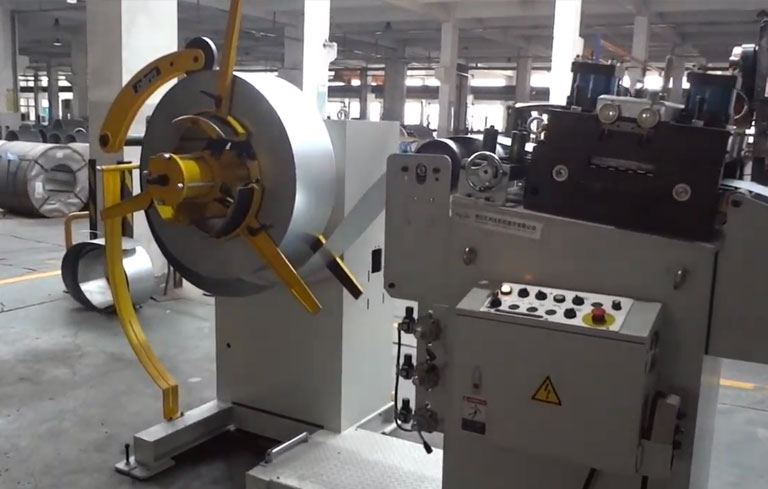

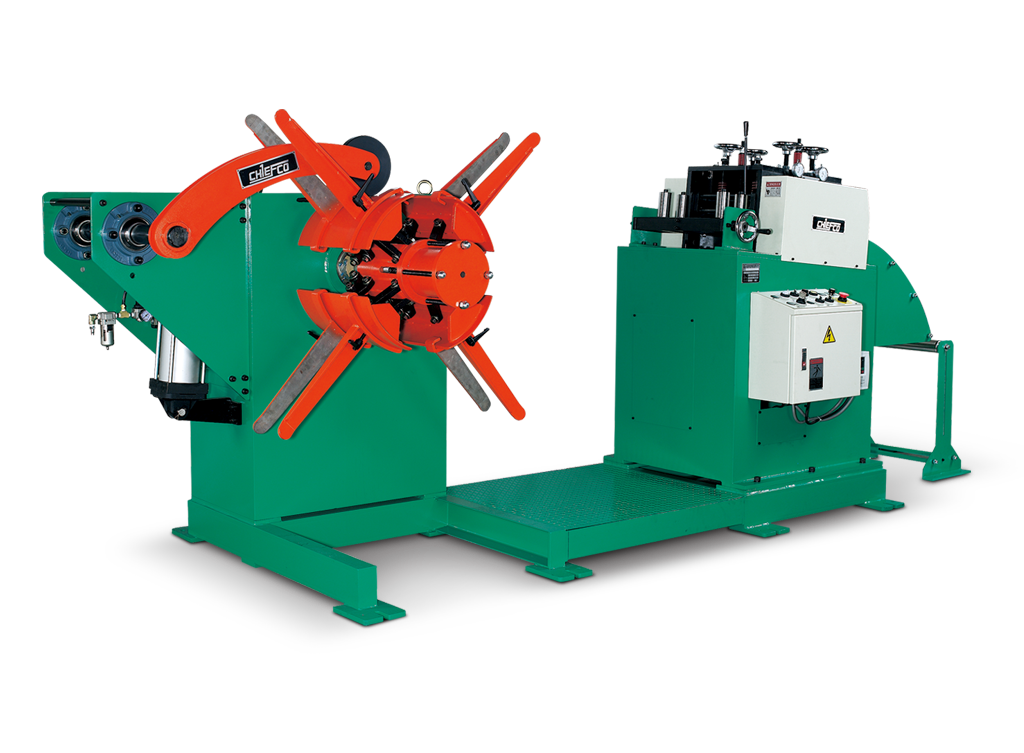

2 in1 Decoiler & Straightener Feeder

- With a suitable radius of curvature, the material will not undergo secondary deformation after leveling.

- Space saving.

- The correcting roller can be tilted, with high flatness and easy operation.

- Highly rigid mechanical structure ensures leveling accuracy.

- High-precision rollers are polished after heat treatment to provide high wear resistance.

- Smooth out-feed control. A frequency converter is included to match the press to control the feed rate.

- Can be used with any brand of feeder. Special design orders accepted.

Decoiler & Straightener Feeder | UL Series

Decoiler & Straightener Feeder | UL Series

Video

DETAILS

| Model | 0320 | 0330 | 0340 | 0350 | 0360 | 0380 | 03100 | 03120 |

|---|---|---|---|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1220 |

| Stock Thickness(mm) | 0.3~3.2 | |||||||

| Model | 0620 | 0630 | 0640 | 0650 | 0660 | 0680 | 06100 | 06120 |

|---|---|---|---|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1220 |

| Stock Thickness(mm) | 0.5~6.0 | |||||||

- General purpose series, choose from 0.3~6.0 mm.

Decoiler & Straightener Feeder | FUL Series

DETAILS

| Model | 0210 | 0220 | 0230 | 0240 |

|---|---|---|---|---|

| Max. Stock Width(mm) | 100 | 200 | 300 | 400 |

| Stock Thickness(mm) | 0.3~2.0 | |||

- Precision type straightener, customer can choose from 13~25 rollers.

DETAILS

| Model | 0220 | 0230 | 0240 | 0320 | 0330 | 0340 |

|---|---|---|---|---|---|---|

| Max. Stock Width(mm) | 200 | 300 | 400 | 200 | 300 | 400 |

| Stock Thickness(mm) | 0.3~3.2 | |||||

- Space saving, can be used with many different products lines.

As the client's prosperity is top priority for CHIEF AUTOMATIC TECH, we adhere to the ideals of "High Quality & Excellent Service", and guarantee these as we innovate new products with attached value and high profitability.

PRODUCT INQUIRY